Editor's note: This is part II of a two-part series. Part I, published in March 2021, looked at the frequency and amount of irrigation growers need, depending on factors such as soil type, weather and plant growth stage. Read it here.

Anyone flying over the western U.S. during the summer can look down and see distinct circular patterns. These patterns are crops that have been irrigated with a center pivot system, an overhead irrigation option that is a common choice for row crop producers. The majority of irrigated acres in the U.S. receive water through overhead irrigation, according to the 2017 Census of Agriculture. This type of equipment carries a large initial investment but is crucial for crop success in many regions.

For specialty crops with wider row spacing, growers tend to opt for drip irrigation, which delivers water along the base of the crop through drip tape.

Hemp is unique in that it can be grown like a row crop or like a specialty crop, so irrigation methods will differ depending on the type of hemp, existing irrigation infrastructure, region and the costs associated with each.

The type of irrigation hemp growers implement needs to be right for their specific operations, so there may not be a true “right” or “wrong” type of irrigation for producers to use. Each irrigation method has its advantages and drawbacks.

Overhead vs. Drip

The type of hemp grown and specific production model used will be major determinants of which irrigation method a grower chooses. Most hemp acreage in the U.S. is dedicated to cannabinoid production using a horticultural model. Drip tape is a common way to irrigate if using a horticultural model, which consists of wider row spacing and lower plant density per acre. This method can also include plastic mulch, but not all growers opt for this.

Drip tape can be used for fertigation, which allows growers to apply nutrients directly to the plant and provide incremental amounts of fertilizer throughout the season. (Many hemp growers are using trial and error to determine an ideal fertilization schedule. See Cannabis Business Times for more on hemp and cannabis fertilization.) However, the drip tape emitter holes where the water comes out of the line can clog, especially if growers use the wrong kinds of fertilizers (i.e., fertilizer that isn’t water-soluble) for fertigation.

Many hemp growers are new to farming, so a drip system is a lower-cost option suited for a horticultural production model. Drip tape, which is laid under the plastic in a plasticulture model, has the added advantage of preventing water buildup between the rows of hemp; this ultimately reduces weed pressure. However, growers with this system will need to pull the drip tape out of the field at the end of each season, which does add some labor costs.

Some cannabinoid producers do use overhead irrigation. This can work, too, especially if growers use a row-crop model and place their plants in higher density per acre than traditional cannabinoid production. If a grower does want to use overhead irrigation in a horticultural model with wider spacing, the water that gathers between rows can facilitate weed growth. However, if producers plant a cover crop or some kind of companion plant in the between-row space, overhead irrigation could offer a huge benefit by watering both the hemp and the secondary crop that is planted between rows.

One major disadvantage to overhead irrigation, especially later in the season, is the risk of disease. While it is unclear if the many different foliar diseases that infect hemp actually cause yield loss, pathogens that cause bud rotting, such as Botrytis and Fusarium, affect the marketable portion of a cannabinoid hemp plant. Rainfall later in the season and insect feeding, among other environmental factors, can also cause bud damage.

Grain and fiber growers are going to use some form of overhead irrigation. With this type of production, drip irrigation would not make sense because plant density is high and row spacing is narrow. The scale at which a grain or fiber crop is produced is generally going to be larger than that for cannabinoid hemp, and it is more efficient to apply water over a very large area by using a sprinkler system.

Growers have options when deciding which type of overhead irrigation to use. Some of them may already have a center pivot system in place and could plant hemp in those irrigated acres. Growers who want a transportable option may opt for a traveler sprinkler system. Up front, this is a lower-cost option than a center pivot system, and the system can be moved to different fields between seasons. However, the energy cost is higher.

The same issue that overhead irrigation presents during flower production in cannabinoid hemp can occur in grain production. The dense grain head, or achene, makes a nice habitat for disease if the pathogen is present, the environmental conditions are conducive, and the hemp cultivar is a suitable host.

We know that hemp grown specifically for grain can survive without irrigation in dryland production because of Western Canada’s history of production over the past 20 years. Much of the hemp produced on our northern neighbor’s farms is grown in the country's drier regions without irrigation.

The key here is weighing the cost of irrigating against the yield loss by not irrigating. An Alberta Agriculture and Forestry analysis of Canadian-grown grain hemp with and without irrigation found that yield was 56% higher in irrigated fields. Gross per-acre revenue based on yield for non-irrigated acres was estimated to be $805, while for irrigated acres, it was estimated to be $1,322. The total per-acre cost of production on non-irrigated acres was estimated to be $409, and the cost for irrigated acres was estimated to be $574. The difference in gross revenue of $517 between the two production methods, and the difference in cost of production of $165, show that, at least in a dryland production system, it pays to irrigate. (In this particular analysis, the upfront cost of the irrigation equipment was not included—just the equipment repairs and labor, fuel and water rates.) Though the U.S. does not have an evaluation for cannabinoid hemp yet, the yield and cost trend is likely similar.

Irrigation Costs

Growers should consider upfront and regular expenses when deciding whether to irrigate. If no irrigation infrastructure exists, growers should evaluate the crop's value and the drought risk. For growers who already irrigate their other crops, it is still worthwhile to look at the hemp crop's estimated value and the seasonal irrigation cost. Doing this may help them decide whether to plant hemp or another crop on their irrigated land.

Upfront irrigation costs can vary greatly depending on whether well or water access is already in place. Drilling a new well or digging a pond may be the most expensive irrigation component. Commercial agricultural wells can vary in cost based on the well's depth and size, the pump and the location. Most estimates include the drilling, the pump and a power source. North Dakota State University estimates the price of a well used for center pivot irrigation to be around $65,000. The higher cost compared to a residential well is due to the need for greater water volume.

Regardless of the type of irrigation a producer chooses, there will be regular costs associated with operating and managing the system. These annual operating costs include the energy to pump water, equipment maintenance, water fees, labor and water tests with possible filtration required.

Testing the water ensures it will be safe for crop irrigation. Water is often tested when a well is first drilled, but it should be tested every couple years after that. To test water, growers can send samples to a laboratory, which will compile a report that includes the water’s soluble salts (total dissolved salts), cations, anions, electrical conductivity (EC) and pH. Labs can also perform bacterial testing. These are all factors that influence plants and could alter the amount of fertilizer used. Growers should not skip this testing. Regular testing may be necessary if using open irrigation ponds.

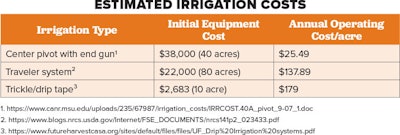

The table above gives a general cost estimate based on several university and USDA publications. The initial equipment costs do not include those associated with obtaining a water source. The costs will vary across the country, so take these approximations as a starting point and seek local experts when creating budget models.

Finding Irrigation Information and Equipment Sources

Irrigation equipment costs can vary greatly. A quote from a supply company is going to provide the most reliable costs associated with different irrigation methods. Some of these companies already are working with hemp growers, so they can provide some expertise for different hemp crops. Local companies also are familiar with the specific needs and common irrigation setups for their regions.

Working with university cooperative extension services is a great place for growers to start when looking for irrigation resources. Both county offices and on-campus specialists have a wealth of knowledge and can often provide contacts for irrigation equipment companies.

Whether hemp growers are using existing irrigation infrastructure or deciding what kind of infrastructure would work best, there are many things to consider. Working with irrigation specialists through a university cooperative extension, crop consulting firms and experts at irrigation companies will help to determine an option that is going to work for a grower’s specific operations. Because certain types of irrigation can be costly additions, weighing the economic benefits against the initial investment and annual costs is necessary to decide on an irrigation type and, hopefully, avoid losses during a dry spell.