While hemp fiber production continues to pick up steam across the U.S., the industry still has a litany of hurdles to overcome. The hemp stalk’s numerous uses require varying processes to produce, and the infrastructure available to do so in the U.S. is still in a fledgling state.

To that end, Charles Cai, an associate research professor at University of California Riverside’s College of Engineering Center for Environmental Research and Technology, has developed and patented a solution that seems like a catch-all. His improved pulping technology for hemp hurd uses a naturally derived solvent, creates no toxic waste, emits no carbon dioxide, converts nearly 100% of the hemp plant into marketable components and eliminates several steps and pieces of equipment in the process.

But Cai, who made Forbes’ 30 under 30 list in 2017 for his invention, didn’t initially set out to improve the hemp industry. When he began developing the Co-solvent Enhanced Lignocellulosic Fractionation (CELF) pulping method nearly a decade ago, he had created it to convert waste plant matter into biofuel.

While that venture is alive and well—Cai has already established a company, MG Fuels, to utilize his technology in the biofuel sector—it’s his work with hemp that has earned him the latest round of funding from the U.S. Environmental Protection Agency (EPA). Cai, along with a team of undergraduate students, recently received a $75,000 grant from the EPA’s People, Prosperity and Planet Program (EPA P3) to improve his pulping method for use in the hemp industry.

“I had two philosophies in doing this: I could not use a chemical that doesn’t come from nature … and I wanted to design a process that doesn’t waste any part of the plant,” Cai tells Hemp Grower. “It only took me about a year to come up with this process and start making it better, but it took up the better half of eight years to prove it.”

The Technology

While hemp is known for its sustainable properties, the current pulping process detracts from its environmental benefits.

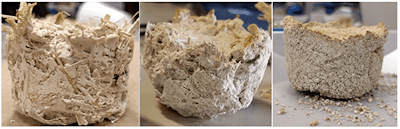

The most prevalent form of pulping technology used currently, called the Kraft process, was adopted from the paper industry and is used to create products such as hempcrete and particleboard. It uses a solution to dissolve the lignin that binds the fibers of the stalk together so the components can be used to make other products. (Hemp stalks contain two components: the bast, which is the stringy outer portion of the stalk, and the hurd, which is the woody core.)

Before pulping, hemp needs to go through a lengthy (and sometimes costly) process of retting and decorticating to dry it and remove its foliage.

Cai says the Kraft process results in a byproduct called black liquor, which needs to be treated before it’s disposed of or burned. Either way, the process results in wastewater runoff and harmful greenhouse gasses released into the environment. Additionally, the byproduct is wasted along with the portions of the hemp rendered unusable throughout the process.

“This is the fate of industrial hemp if we don’t improve upon the pulping process,” Cai says.

Cai’s CELF method uses water combined with a natural substance called tetrahydrofuran (THF) to break down the lignin at lower temperatures than traditional methods.

He likens his process to a crockpot. The CELF process separates the hemp into four streams: pulped fiber, lignin, extractives (such as cannabinoids) and sugars.

Cai says each stream has marketable applications. The pulped fiber can be used for building materials, the lignin can be added to bioplastics, extractives can be used in wellness products and the sugars can potentially be added to food products—and these are just the beginning.

In studying the CELF process’s application to hemp, Cai also discovered the hemp does not need to be retted, dried or decorticated beforehand. He found the decorticated hemp resulted in the same products as raw biomass when run through the CELF process.

“How much in labor costs can you save if you’re not needing to filter, sort, sieve, ret, dry and then decorticate?” Cai says. “By saving those costs, it means you can bring that value back to the farmer.”

What’s more, the process results in only 1% waste in the form of mineral ash—and Cai says that mineral ash can be used as a soil amendment.

While the process results in numerous products, Cai cautions that it isn’t applicable to all products that can be created from the hemp stalk.

“Making yarn or textiles from hemp is a very different process than making other things from hemp, like hempcrete or hemp board. When you’re trying to retain the [bast], you actually damage the rest of the plant,” Cai says. “This process is not an all-in-one. It’s not supposed to completely replace all things hemp. It’s just supposed to [help] those people who are interested in getting to the hurd [and make] their jobs easier.”

Gaining Legitimacy

Cai says his process has been in the works for years, but passage of the Agriculture Improvement Act of 2018 (the 2018 Farm Bill) opened the doors to study hemp. Then, last year presented a breakthrough.

In 2019, Cai was able to prove CELF’s efficacy to the scientific community using a supercomputer. The process was published in the Journal of the American Chemical Society that year.

Since then, Cai has also received an international patent for his process.

Cai also applied last year for the EPA’s P3 program, which has two rounds of funding. He received a $12,000 grant that year to create an improved type of hempcrete.

From there, his experimentation in the hemp space took off.

“Afterwards, we found so many other great things about it,” Cai says about discovering the numerous other byproducts the CELF process created from hemp.

This year, Cai applied for phase two of the P3 program and received a $75,000 grant.

Cai and his team have now partnered with existing hemp companies, such as InnovaCan, Hempire USA, Match Patch Pro and The Hurd Co. to identify new products and market opportunities for hemp run through the CELF process.

“This is essentially like, OK, not only the federal government, but also the industry, is still very interested in what we’re doing,” Cai says.

The Future

With new partners in the hemp industry and a fresh round of funding, Cai is now looking to raise the rest of the funds he needs to build out his first physical pilot processing equipment specifically for hemp.

Cai says he is looking to raise $2.5 million to build a one-ton-per-day machine “to specifically demonstrate the CELF process for hemp pulping and hemp processing." (Cai has already created physical models able to process 30 tons of biomass from his work in the biofuel sector.)

He ultimately envisions building out small plants across the country to house the pulping equipment, which he says is not technically sophisticated and can be operated by an average person.

In addition to being a cleaner process, Cai says CELF is likely to be cheaper process, too, that can ultimately generate more revenue for producers.

“If you do it this way, you use the whole plant,” Cai says. “Because you use the whole plant, the whole thing becomes useful, and it will fundamentally change the economics [of the industry].”

For inquiries about the technology or partnerships, email Cai at [email protected].