Very few people who invest their time, their money or, like most of us, both their time and their money in a business would consider operating without financial records. So why do some operate without a clear set of standard operating procedures (SOPs), the written instructions that an organization follows for specific processes? Good SOPs, like good financial statements, convey information clearly and reflect changes in operations.

At CTPharma, we use SOPs in a similar way in each major aspect of our operations. We systematically record the way we do things, and we record the results. When someone seems to have a good idea for improving an aspect of our operation, we record a change in the appropriate SOP through “change control” and measure just how good the idea is. For example, if we shorten the grow cycle in any way to get more cycles per year for a specific cultivar with specific characteristics, how does the change affect our yield? How does it impact the characteristics that our market values in the cultivar?

We do not like theoretical discussions about cannabinoids nor terpenoids nor about anything else. We prefer data. When an idea looks promising, we test the idea while controlling all other meaningful variables. We keep constant the other variables, like light intensity and duration at each stage, fertigation and fertigation timing. Within our SOPs, when we decide that we have a good reason to do so, we can also change two or three variables. We constantly test new ideas and, based on the results, make changes to our operations. We do not, however, argue into the night about the next good idea.

Why SOPs?

In the grand scheme of things, one can argue that the control offered by a functioning SOP system ensures product safety and quality. The argument is valid. One can also argue that the SOP system increases profitability. This argument is also valid.

Nothing that we do is specific to cannabis; our SOPs are the same as the SOPs for conventional FDA-regulated food and drug manufacturing in the U.S.

Let’s start with safety and quality. U.S. history contains two notable national reactions to dangerously contaminated or toxic food and drugs. The first reaction resulted in the 1906 Pure Food and Drug Act, which prohibited the sale of adulterated or mislabeled food and drug products and led to the creation of the Food and Drug Administration (FDA). Upton Sinclair’s descriptions of meat-packing industry practices in Chicago, supported by evidence of contaminated packaged meat products, generated a national furor, and politicians responded.

The second reaction resulted primarily from a single product, S.E. Massengill’s Elixir Sulfanilamide, which in 1937 killed about 100 Americans, many of them children. The FDA existed, but after that tragedy, President Franklin Delano Roosevelt and Congress gave the agency enforcement powers with the Federal Food, Drug and Cosmetic Act. In 1960, Congress again expanded the FDA’s powers when an agency reviewer, Frances Oldham Kelsey, stopped the approval in the U.S. of thalidomide, a drug that was later found to cause birth defects in thousands of children. The historical photographs of European children with severe birth defects remain extraordinarily disturbing.

The result of these unfortunate events in U.S. history has been a regulatory demand for production in a state of control, with SOPs at the heart of that control. This leads to more predictability without any drama. Indeed, our ability to control of every step of the process should mean that our lab results merely confirm what we knew all along. To be clear, we are entirely in favor of lab testing. We are pleased, however, to leave out the drama. Nothing that we do is specific to cannabis; our SOPs are the same as the SOPs for conventional FDA-regulated food and drug manufacturing in the U.S.

So now we have our product, clear of contaminants and with the test results in terms of potency and other characteristics just as we expected them to be. Through our SOP system, we also have created the elements of continuous improvement methodologies, such as Six Sigma or lean manufacturing, to reduce variation. For example, lean manufacturing involves the use of standardized tools to reduce waste, while Six Sigma employs statistical analysis to eliminate defects. We measure inputs throughout the process, such as watering or light schedules, and adjust as needed to ensure we get our desired results.

By documenting each of our operating processes with our SOPs, we avoid interminable discussions of what went wrong. Presented with an issue, we can always ask ourselves, “What changed?” (Not too much ever changes.)

So far, we have discussed our SOPs from the company’s point of view. We want great-looking, great-tasting products. We want to create those products at the lowest possible cost. We want the products to be consistent and to attract a loyal customer base. We want the products to warrant a premium price from our customers. We believe that our SOPs do a lot to strengthen our quality and profitability.

SOPs on Defense

Good SOPs can also play defense. We do not want complaints, negative social media, boycotts, lawsuits nor legal liability. Producers across various states operating in less-than-optimal conditions have faced all of the above. Of course, the same issues have befallen other consumer products and producers across the U.S. We should all be aware that plaintiffs’ attorneys follow consumer complaints and regulatory actions. Class-action lawyers evidently have found public reports of these matters to be an excellent source of business. We should also be aware that neither we nor our industry are immune to consumer complaints or ridiculously expensive lawsuits, as they happen most years in most states.

Avoidable waste and lost profits frighten us. A consumer illness is inconceivable to us at CTPharma. We use good SOPs to defend ourselves from anything that can go wrong. Our final SOPs concern our retained samples of each of our products, on which we conduct stability studies. In our stability studies, we examine what happens to a sample of a packaged product over time.

By documenting each of our operating processes with our SOPs, we avoid interminable discussions of what went wrong.

Those retained samples and stability studies are our ultimate defense against production mistakes and unwarranted complaints. We rely on our SOPs to present a consistently effective defense against everything that could go wrong in our operations and against baseless complaints. (We too are familiar with customers in conventional consumer industries who have removed caps from bottles of product and complained about product evaporation.)

Good SOPs require more commitment than money, but useful SOPs are not free. That said, SOP templates are available online. They should be simple and straightforward. If you have to meet certain regulatory requirements, for example, the SOP should reflect that (e.g., at which points during the production process you must test a product).

SOPs get written in the beginning, before problems get ugly and before we have our good ideas for improving our operations. They work really well at keeping us profitable. Our SOPs and our profits improve over time. Employees who interact with plants and processes make suggestions; managers who oversee those employees modify SOPs. Everyone is trained the same way thanks to good training logs that are properly maintained and updated. The SOPs evolve constantly through the change control process, which is an SOP itself meant to make writing new SOPs intuitive and obvious. Some key elements to include in an SOP include the hours of light and darkness, watering protocols, and harvesting methods.

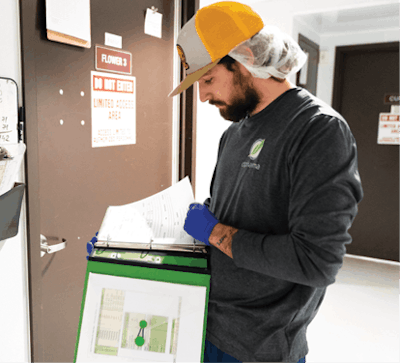

The CTPharma team is always eager to show off our SOPs to regulators, bankers, insurance brokers and anyone else who might be concerned with how well we control our operation and how well we present ourselves to the world. Our processes are extremely well organized in voluminous binders. We make it obvious that we systemize our practices, that our systems rarely break down and that they are scalable.?

We regard much of the War on Drugs as a war on science, one that we can win with good methods and good science that also happen to yield operational and financial stability.

Rino Ferrarese is co-founder, president and COO of Connecticut Pharmaceutical Solutions, one of four licensed producers in the state. He has experience as a compliance officer working in FDA-regulated industries under the guidelines of current Good Manufacturing Practices (cGMP) for the production of prescription, over-the-counter and homeopathic human drug products. He is a certified Six Sigma Black Belt and ISO auditor. Ferrarese also works with Elite Cannabis Enterprises, developing and submitting competitive medical marijuana license applications for clients across the United States.