Building the right working environment that allows employees to blossom and perform at their peak will result in the best productivity, highest yields, and greatest product quality.

This idea sounds simple–but, if you’ve been working in the cannabis cultivation industry long enough, you realize it isn’t always easy to do.

Usually, it all starts out great. But then team members get burned out. Mistakes get made. Interpersonal frustration can creep in. Then productivity suffers, and people leave.

If you’re facing more turnover than you’d like at your cultivation business, or you find that employee productivity isn’t what it once used to be, you’re not alone.

This is really hard, physically laborious work, and it can be challenging to keep spirits high and productivity going year-round with all of the market swings, changing regulations, and operational challenges. Not to mention, most of the work done in cultivation is tedious, repetitive work indoors in rooms with no windows or natural lighting.

Secondly, a waning culture doesn’t necessarily mean you have a bad business, nor does it mean you don’t value your team. Granted, there are folks that will try to push their teams too hard, pay them too little, or fail to show their appreciation. But we’d argue that most cultivation businesses that face these issues just have a few kinks to work out as it relates to these three areas:

- Organizational structure,

- Setting the right expectations, and

- Accommodating employees.

The good news is this problem is entirely fixable. You can remove the friction from your workflow and instill pride in your team–and these positive changes will directly translate to your yield, quality, and ultimately, sales.

1. Structure Your Cultivation Hierarchy Properly

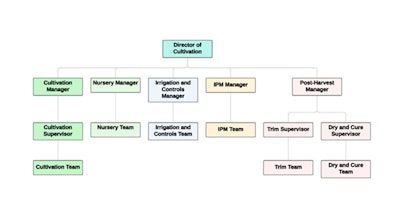

Perhaps your cultivation organizational hierarchy looks like this: You have one Director of Cultivation (or VP of Cultivation or Chief Cultivation Officer) who leads all your growing operations, and the rest of your cultivation team reports to them.

That model can work in the beginning as you’re building your team, but it falls apart in the long run, and here’s why. Your Director of Cultivation is only one person. They’re likely deep in the horticultural data, making strategic cultivation decisions for pest control, irrigation, nutrition, pruning and defoliation–maybe even post-harvest, too. They’re also simultaneously making staffing schedules, liaising with your sales and marketing teams about genetics selections, keeping track of Metrc or other seed-to-sale software, as well as managing the day-to-day of the entire team. Not to mention, unexpected personnel issues always creep up, as do crop issues, which they also need to balance. This is all just too much context-switching for one person to do the job properly without things slipping through the cracks.

Instead, a vertical organizational structure that looks more like this can ensure one person isn’t pulled into too many directions:

The same goes for post-harvest. For larger facilities, there is an enormous amount of trimming, inventory tracking, data capture and analysis, and other technical work happening throughout drying, curing, and trimming. To get the highest quality product with minimal loss, it is important that this technical work is assigned to specific people who are responsible for the outcomes, which is planned and directed by a higher-level manager.

In a simple world, one could just hire a manager and put that person in charge of a bunch of people, producing a flat organizational structure. This dilutes accountability and creates an environment where nobody (except that singular manager) is directly responsible for anything. This tragedy of the commons leads to lower quality outputs, more mistakes, and a general lack of overall care. The goal is to foster a culture where employees feel a strong sense of ownership over their specific role or function in the facility. This directly improves pride, workmanship, dedication, and overall company morale.

Think about it this way: When someone is laser-focused on irrigation, for example, they can eliminate distractions from everywhere else. They’re committed to the task at hand of capturing and analyzing data that allows them to home in their irrigation strategy and validate the results constantly. Ultimately, this will allow them to crop steer and lead to better consistency and vast improvements in both quality and yield, which results in a direct benefit to the bottom line for your company.

When team members can commit their brainpower to something specific for extended periods of time, they get into a flow state. This is where they’re so immersed in their work where time passes quickly, and they feel in control and empowered. A focused role helps people become experts at their thing. They just get better and better at it over time–and that gives your company an edge. Additionally, that person’s name is attached to their work. They are inevitably going to work harder because they are either going to be praised for doing a great job or have their feet to the fire if the work is poorly handled.

One question comes up a lot with cultivation business owners: Is there enough work to justify these specialized positions? There is always something that can be done to improve operations if someone was putting all their energy into it. Having highly technical roles and teams allows employees to hyperfocus on their specific area and work to continuously improve it for the benefit of the company. Producing a quality cannabis crop consistently happens when small aspects come together perfectly, and workers are dedicated to these nuanced functions to focus on the finer details of the process.

On the other hand, when the responsibility and accountability is diluted, processes remain stagnant, tolerable issues go unfixed, specific data goes uncaptured, and precision tuning does not happen. Workers must choose which issue to focus at any given time, and in times of crisis or high workload, the finer details and less immediately critical issues inevitably receive less attention.

This kind of organizational chart is what is required to produce quality product, and the extra cost is far overshadowed by the increased yields and improved product quality. Having additional specialized roles with accountability for specific functions also tends to reduce the overall headcount because the team operates more efficiently.

Here are some examples of specialized roles and teams that we have seen breed success and excellence in cannabis facilities:

● Irrigation and Controls

● Plant Inventory and Data Tracking

● Integrated Pest Management

● Propagation / Tissue Culture / Clones + Mother Plants

● Plant Care and Garden Work

● Harvesting and Room Cleaning

● Drying / Curing

● Trimming

● Facilities Maintenance and Cleaning

These are all functions of your cultivation operation that take an enormous amount of time, energy, and expertise. It makes sense to dedicate people to each of these roles to make sure they’re done correctly.

The one potential downside to this vertical model, however, is that it has the potential to create silos within your company. Therefore, it will be important to continue to find ways to come together and celebrate your team’s strengths and accomplishments to form a collaborative culture. In a robust hierarchy, communication from upper- and lower-level management positions is crucial because it fosters interdepartmental understanding. This provides high-level managers with the information to delegate properly and formulate strategies with operations and sales managers. Weekly sales meetings, crop planning meetings, and collaboration software that pulls in members from cultivation, post-harvest, packaging, fulfillment, and sales teams all go a long way to assisting with overall communication, discourse, and transparency.

So, the question now becomes: How many people do you need on your team? Your company should have one full-time employee in cultivation per 1,000 square feet of vegetation and flower canopy. If you run a 25,000-square-foot canopy facility, that’s 25 people (including department leadership). This is based on having automated irrigation and controls systems and will increase substantially (up to double) if the team is hand-watering plants and gathering climate data manually.

2. Define Expectations at the Outset

Cultivation is also not always a standard 8-to-5 job where you punch in and out at the same time each day. This is agriculture, and workers must remain present until the plant work gets done on schedule. Sometimes that means longer days. Sometimes that means holidays. It’s just the reality of the work; the plants do not get to take a day off.

During the job interview process, it’s critically important to convey these things at the outset. Failing to acknowledge this with your potential hires will lead to dissatisfaction once they realize the physically demanding nature of the work. This often leads to resentment and bitterness–which will be a major detriment to your company culture.

Even after you’ve set those expectations, if workers are continually asked to do more with less, this will also lead to disappointment. You won’t be able to earn the respect of your team and encourage them to own and complete the job if they’re perpetually exhausted and using worn-out or faulty tools and equipment.

When your employees sign onto cultivation, they’re agreeing to make certain sacrifices. They’re breaking the psychological barrier of having a “normal” job to work in cannabis. Therefore, companies should also break their own psychological barrier of 40-hour work weeks when the situation calls for it. That means being flexible with workers’ hours, such as letting your team leave early if the work does get done so they can get some of their time back. This can sometimes be an easy incentive to drive output: complete the task quickly, and you can spend more time with your family or doing the things you enjoy outside of work, especially if there have been days in the same pay period where workers were required to stay late or put in extra hours.

Some of my most productive days as a leader have been when we set a big yet achievable goal and allowed the team to leave early if they reached it. It’s incredibly motivating. We’ve tried incentivizing with a little extra cash, creating competitions, and other ways over the years–but we’ve found that these methods do not work nearly as well. People value their time way more than we give them credit for. Remember: Rest is productive!

3. Accommodate Employees

The other part of the formula for an improved culture with peak productivity is properly setting the expectations of your team and accommodating them with what they need to succeed.

When people join your company–especially if you’re operating in a newer market–there’s a honeymoon period. People are eager to work with the plants every day because they’ve never been in that type of environment before. They’re working in weed! They get lost in the beauty of the plant and all the smells and colors of their first rounds. It’s exciting.

However, that excitement can wear off quickly. Cultivation is tough. Grow rooms are hot and humid, not to mention the effects of high-powered grow lights and elevated CO2 levels. The tasks can be both tedious and physically demanding, requiring workers to be on their feet, or in odd positions, e.g., seated with arms outstretched for hours at a time.

With these difficult working conditions, it is important to plan for and listen to the ergonomic needs of your employees.

Some examples to help accommodate employees and make them more productive while working in these conditions include:

- Providing snacks and water for employees so that they can stay energized

- Providing and maintaining comfortable stools, step ladders, fatigue mats, etc.

- Ensuring that during the design phase, adequate working space is created for employees to comfortably navigate between aisles while completing plant work

- Timely replacement or repair of broken or worn-out equipment

- Providing proper PPE such as sunglasses, gloves, uniforms, goggles, etc. for employees to be safe on the job

- Fostering a culture of cleanliness in all working areas. Decluttering spaces helps to declutter the mind, and cleaning as you go helps keep things tidy without becoming a huge task

When structuring your organization, a proper hierarchy with specified roles will create layers of accountability and insight into the day-to-day operations. By setting the right expectations of the demanding and sometimes unpredictable nature of cultivation, workers have a clear vision of what they will be dealing with at their job. Establishing these things within the culture of the organization and providing the proper accommodations will foster a level of trust, understanding, and willing communication that will drive output and employee morale to their highest potential. A company is only as good as its people, and empowering the people creates a cyclical benefit to all.

Jeremy Shechter is the Chief Operating Officer (COO) of Bickel Consulting—where he oversees development and design of cultivation facilities, operational plans, SOPs, and much more for Bickel’s commercial cannabis clients in more than 15 states. His focus is on the implementation of advanced controls, automation, and irrigation systems for clients and utilizes a vast network of vendors, partners, and specialists to make projects streamlined and successful. Jeremy has worked in the regulated cannabis industry since 2017, where he served as VP of Operations for Buckeye Relief, one of Ohio’s largest and most successful cannabis companies.