When visitors step into Pacific Reserve, a one-word reaction often follows: Wow. The crop in its cathedral-like Monterey County, California, greenhouse has that effect. Once the senses regroup, the hum of activity surfaces. From breeding and popping seeds to marketing and distributing its carefully curated brand, Pacific Reserve has a lot going on in-house, part of a conscious decision to control the company’s destiny and remain nimble as the state’s market evolves and business and operations lessons are learned.

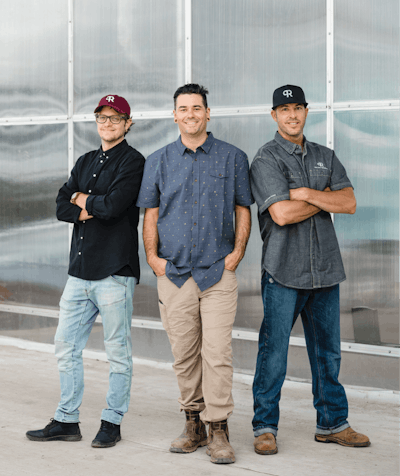

For co-owners Brook Eagle, William Tomlinson and Andy D’Amico, the venture represents the synergy of their decades of growing experience, sacrifices made and a shared vision to bring the cannabis industry their very best.

Common Bonds and Beginnings

Pacific Reserve’s partners came together in 2016 when Northern California’s Monterey County (home to Salinas) opened to cannabis cultivation. Tomlinson and Eagle were founding members of The Guild collective in San Jose; D’Amico was a co-founder of cannabis-infused confectioner Day Dreamers Chocolate. While working separate projects on a shared Salinas Valley property, they connected.

All three have grown under California’s Proposition 215, the Compassionate Use Act of 1996, for more than 20 years. “We really found a common sense of hard work ethic and respect for each other,” Eagle says. “We’re deep in the culture. We believe in the plant, what it can do for our economies and for people’s health and well-being.”

In April 2017, the trio left their existing brands to start Pacific Reserve. Other than a minimal initial raise, they’ve bootstrapped and self-funded the project. “We take a lot of pride in that,” Eagle says. “We’ve gone through our ups and downs but have really built this farm from our own blood, sweat and tears.”

Monterey County only allowed cannabis cultivation within existing greenhouse and industrial buildings. (A pilot program allowing outdoor cultivation was just approved in June.) The team set up on a former floral farm that offered two greenhouses: one 3-acre structure (130,680 square feet) allocated to the nursery business, and one smaller 36,000-square-foot greenhouse for flowering.

With their experience and access to extensive genetics, concentrating on nursery production made sense. Monterey’s cannabis business taxes provided motivation, too: Fiscal-year taxes were $15 per square foot for flowering canopy versus $2 per square foot for nursery.

Pacific Reserve’s nursery offered commercial growers Grodan-plugged clones, 10- to 12-inch “teens” in 4-inch pots of organic soil and “ready-to-flower” plants. Learning and improving were priorities. “We built better environments, we figured out better protocols and really fine-tuned our nursery business,” Eagle shares.

Timely Pivots and Flower Expansion

As Pacific Reserve’s nursery business grew, the company encountered some unexpected obstacles. Compliance became an issue but not in the way people might expect.

“We’ve really been on top of our game and tried to be uber-compliant here,” says Eagle, Pacific Reserve’s compliance point person. One reality of being compliant was discovering that many other cannabis businesses weren’t, which significantly limited potential customers for compliant businesses like Pacific Reserve.

During that time, Monterey County also changed course. Effective July 1, 2018, fiscal-year nursery taxes dropped to $1 per square foot, but the mixed-light cultivation taxes that had been cost-prohibitive for Pacific Reserve dropped from $15 to $5. “That brought [flowering canopy] down to a rate that was competitive with other counties in the state, like Humboldt, Mendocino and Santa Barbara,” Eagle says.

One advantage to being owner-operators, especially in a volatile industry, is agility. “We make all the decisions, the three of us, and we aren’t afraid to make fast and decisive decisions,” Eagle says. When the tax rates became more competitive in Monterey County, Pacific Reserve expanded flower production and began focusing on wholesale flower sales.

Moving toward the wholesale market offset inherent nursery challenges like the seasonal nature of the business. Most of Pacific Reserve’s greenhouse-grown starts go to greenhouse and outdoor growers rather than indoor growers. “There’s a little bit of a hard transition to go into indoor facilities with plants that have been hardened off outside,” Eagle explains. The seasonal business peaks from April through July, then client gardens harvest and either slow down or take winter off.

Pacific Reserve scaled its nursery back to exclusively produce clones and teens, built out roughly half the former nursery space for flowering, and supplied other California brands with its flower. The company is planning another 75,000-square-foot expansion for greenhouse flower production over the coming year.

As 2018 ended, many people forecasted a massive California cannabis surplus for 2019. Eagle, Tomlinson and D’Amico disagreed. From their perspective, people weren’t clearing regulatory hurdles fast enough. They foresaw a shortage of compliant, licensed flowers for retail shelves. That’s when they decided to launch the Pacific Reserve brand. “We were right in our predictions,” Eagle says.

Brand Creation and In-House Control

Pacific Reserve continues to evolve as the business grows. The company discontinued wholesaling flower in December 2018 to focus on its new line. “Our brand is a Pacific lifestyle brand that reflects where we came from, where we’re living now and the West Coast culture of cannabis,” Eagle explains. “We’re not just a hip-hop culture or a hippie culture or a surfer culture. We’re part of the cannabis culture of the West Coast. That lifestyle that encompasses all those things.”

Initially, the brand relied on other businesses for non-production work, from rolling pre-rolls to distribution, but that soon changed. “We just found a lot of inadequate work being done in the space for us,” Eagle shares. “We found that the majority of the industry was still very immature from where we needed to be.”

So, the company successfully applied for processing, manufacturing and distribution licenses, moved everything in-house, established standard operating procedures (SOPs) and expanded its team—all devoted to Pacific Reserve’s brand. The only exception is extraction; an outside extractor produces crumble from Pacific Reserve’s product for the crumble-infused joints Pacific Reserve rolls.

The move reduced costs in some areas and increased it in others, but it’s all part of the curve. “We are learning throughout all these processes,” Tomlinson says. “We’re all smart enough and capable enough to see where the inefficiencies are and become more efficient. … Every month, we’re refining our processes, so in turn it’s becoming more cost effective.”

The brand is currently in 80 Northern California dispensaries. Its SoCal launch is expected sometime in August.

Each cultivar carries its own distinctive product label that reflects an aspect of the lifestyle Pacific Reserve is all about—from Pacific landscapes to a ’67 Impala—all designed by the company’s in-house designer.

The team has learned from other’s mistakes, as well. “We’re big proponents of making sure we have the infrastructure there to produce this product before we go out and market our brand,” Tomlinson says. “We’ve been very cautious about how we approach the market. When we go down to Southern California, we know that we’re going to have the product to keep supplying these stores to maintain that shelf space.”

Cultivation Continuity and Organic Priorities

Pacific Reserve’s organic greenhouse approach differs little from nursery to flower. “We really believe greenhouse [cultivation] grows the highest-quality medicine for the most-efficient costs, and we compete with the indoor-grown out there, in the sense of THC potency and quality of flowers,” Eagle says. “We also think that sun-grown brings a uniqueness out in the cannabis that indoor can’t.” Pacific Reserve supplements with lights in winter; the rest of the year, its plants just receive full sunlight.

Pacific Reserve plants are soil-grown in fabric pots on the ground, with an emphasis on organic soil and multiple organic inputs to create a full spectrum of macro- and micronutrients. Fabric pots allow roots to air-prune and grow larger, Eagle explains, while porous soil allows more feedings and air to the roots.

“A big thing for us is that we are cannabis users,” Eagle says. “We’ve been smoking cannabis for most of our lives, and we want to produce something for our customers that we can stand behind and that we would use. Organic inputs become really important to that.”

A Dosatron irrigation system with timed drip emitters waters multiple times a day. Eagle tests soil and leaf samples every two weeks. “I know what the plants are uptaking, and I know what’s in my soil, and then I feed accordingly,” he says. “We’re letting the plant and the soil, its food base, tell us what it needs so we can grow them optimally and not feed too much nutrients or feed too little, which saves us in costs.”

The team’s integrated pest management (IPM) strategies include predatory insects and proactive organic sprays for expected pests. “IPM to us isn’t the sense that we’re always 100-percent bug-free. It’s the sense that we’re out in the world where there’s always going to be bug pressures. We just need to deal with them, so they don’t overtake a crop,” Eagle says.

The brand keeps 16 cultivars (a mix of sativas, indicas, hybrids and CBD-dominant varieties) in production and switches them all three times a year. Some go straight to pre-rolls, others to jars.

Current flower production runs about 12,000 pounds annually. Monthly nursery production runs about 140,000 clones, some of which become teens for sale or stay in-house. Automation is used only in packaging; everything is hand-trimmed, and all processes are designed to treat flower very gently.

Goals That Transcend THC

Eagle, Tomlinson and D’Amico are currently building out 12,000 square feet for breeding and phenotype selection. Eagle, the primary breeder, says the company has collected about 400 genetics and a stable of 15 different males for in-house breeding purposes.

Eagle focuses on uniqueness and compatibility with the Salinas climate (think foggy mornings and botrytis threats). Breeding for THC isn’t always the priority, even though the California market accentuates it.

“We still hold on to the value of terpenes and how it tastes,” he says. “Sometimes your bud may test at 15 percent, but with the right terpene, you’re getting just as high as if you’re smoking a flower that tests out over 20 percent. I like to find stuff that has a lot of uniqueness, so that’s always one of my goals. Then just breeding some strains that are consistent, yield well, test high and have amazing terpene profiles.”

Pacific Reserve’s top-selling genetic is Ruby Slippers, a sativa with what Eagle describes as a soaring high and beautiful deep red color to its stems and the slipper-like undersides of its leaves. “It was bred by a friend but selected by us out of a few thousand seeds, so it’s definitely kind of an in-house strain,” Eagle says. “We’ve been slowly getting it out, but we’re about to have a lot of that out to the market.” Another favorite is Don’s Delight, a 20:1 CBD-dominant strain bred by D’Amico for a friend undergoing chemotherapy.

Plans are to release more genetics bred at Pacific Reserve soon—like Gypsy, a high-potency WIFI 43 x Boil Over cross that Eagle describes as having strong floral terpenes and uplifting, anti-anxiety highs. “We scrutinize our genetics really hard,” Eagle says. “When we do release them, I think that people are really going to find them very pleasurable, not only in smells and tastes but also in the effects that they cause.”

#FromOurFarm

Pacific Reserve’s marketing materials prominently feature the #FromOurFarm hashtag. The tag is more than a marketing tactic to Eagle, Tomlinson and D’Amico; it beckons back to their roots, growing on their own small farms under Proposition 215, and everything they and their families endured to make their dreams a reality.

“We really want to convey the message that we’ve made the decision and gone through all the struggles to control our own destiny,” Eagle says. “We’re not buying flower from another grower, we’re not using another distribution [company], we’re not trying to have a third party market us. Literally everything we’re doing is around this one table here at this farm.”

Tomlinson adds, “It’s really just portraying what we’re all about here and what we’ve sacrificed to get to this point—and how we’re really going to stay true to ourselves and our love for this plant that has brought us so much joy throughout all these years.”