Carbon dioxide is essential for all green plants’ growth. According to a research report from Climate Central (an international group of scientists studying climate change), the globe’s level of carbon dioxide (CO2) in the air has reached 410 parts per million (ppm). Research has shown that many crops, including cannabis, benefit from 900 to 1,200 ppm. The optimum level depends on light intensity, temperature and maturity stage. It is most effective during the bud to flowering stage.

Things to consider:

- The CO2 in the air in a greenhouse or grow room can be depleted rapidly by actively growing plants. Plant growth ceases when the level gets below 200 ppm. A level above 1,500 ppm is not economic. A level above 5,000 ppm can be lethal to humans. Research has shown that levels of 800 to 1,000 ppm can increase cannabis yields 10 percent to 25 percent.

- CO2 is only effective for plant-growth enhancement when there is light. In greenhouses, it is supplied starting early in the morning while it is cool. Once the vents are opened or fans activated, CO2 addition is stopped, as the cost usually exceeds the benefits. In growth rooms, it can be added as long as the temperature is below 90°F and the minimum light level is about 900 foot-candles. (A foot-candle is a measurement of illumination, “equivalent to the illumination produced by a source of one candle at a distance of one foot and equal to one lumen incident per square foot,” according to Random House Dictionary.)

- Supplying CO2 from the combustion of fuel adds heat. In greenhouses, this is an advantage during winter, as it reduces the heating bill. During warm weather, the heat must be removed by ventilation or air conditioning. In growth rooms, lights usually give off too much heat, so tank-type CO2 should be used.

- Carbon dioxide is heavier than air, and distribution is best achieved with horizontal air flow (HAF) fans, turbulators, or fan and tube ventilation.

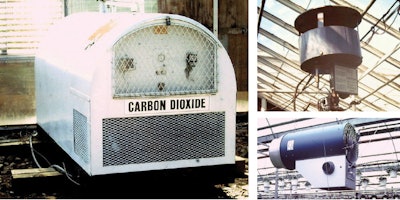

The two sources of CO2 used in commercial cannabis production are compressed liquid gas and combustion of fossil fuels (natural gas and propane). Each has its pros and cons. Other not-so-common sources are fermentation, CO2 bags, compost and dry ice.

Compressed Liquid CO2

For grow rooms and small greenhouse operations, manufactured CO2 is usually the best choice as it is convenient to obtain and handle, and usually has no contaminants. It is purchased as a compressed gas by the pound (lb.) and supplied in pressure cylinders from 20 lbs. to 100 lbs. Cost is about $1.30/lb. for small cylinders to $0.70/lb. for larger ones. Small cylinders can be purchased and usually returned to the supplier for a full replacement tank (similar to a propane tank for an outdoor grill). Larger ones may also be purchased. A 100-lb. cylinder costs about $500. CO2 is also available in bulk for grower-owned larger tanks for about $0.50/lb. A refrigeration system is included with the tank to maintain the temperature at 0°F to keep it in the liquid state.

One pound of compressed CO2 yields about 8.5 cubic feet (cf.) of gas. At $0.70/lb., cost is about $0.08/cf. It is usually distributed above the crop with ¼- to ½-inch of plastic tubing with 1-mm holes spaced about 12 inches apart. Besides the tank, equipment required includes: a pressure regulator to reduce the tank pressure to about 5 pounds per square inch (psi), a flow meter that adjusts the rate of flow, a solenoid valve that shuts off flow and a timer/controller that activates the solenoid. Hardware includes piping and fittings.

Combustion of Propane and Natural Gas

In larger greenhouse operations, non-vented combustion of propane or natural gas from burners is commonly used. CO2, along with heat and water, are byproducts of combustion. The heat generated supplements the normal heating system during cold weather, but would have to be vented during the summer. About 0.8 gallons of water are given off when burning 1 gallon of propane, or 1.1 gallons when burning 100 cubic feet (ccf) of natural gas. This can increase humidity to excessive levels if it is not removed. A dehumidifier or ventilation system may be needed.

All fuels contain sulfur, some more than others. During combustion, sulfur is converted to sulfur dioxide. If sulfur dioxide leaks into the greenhouse and combines with the moisture in the air, sulfuric acid is formed. A level as low as 0.5 parts per million, when it condenses, can cause burn spots on the leaf surfaces of some plants. Long-term, low levels of sulfur dioxide may result in flecking and premature leaf drop. To avoid this, purchase gas with low sulfur content.

Burning a fuel requires oxygen, so makeup air is required. About 1 square inch is needed for each 2,000 British thermal units/hour (Btu/hr) of heater input. A 60,000 Btu/hr generator, such as the Johnson Gas CO2 generator (about $1,500), will require 30 sq. in. or a 6-inch. diameter pipe.

If natural gas is being used, make sure sulfur content is less than 1 grain (64.86 mg) per 100 cubic feet. If you are burning propane, use an H.D. 5 grade. Natural gas will yield about 105 cf./ccf. At $1/ccf., cost is about $0.10/cf. Propane yields about 108 cubic feet of CO2 per gallon. At $2/gallon, the cost is about $1.85/cf.

How Much CO2 Is Needed?

The total CO2 that should be added is the amount the crop needs plus the amount lost by infiltration. The average rate of plant usage is between 0.002 and 0.004 cubic feet/hour per square feet of floor area.

Greater amounts may be used on sunny days or with high artificial light for crops with large leaf areas such as cannabis. For example, for a 30-foot by 128-foot greenhouse with a plant usage rate of 0.0003 cu. ft./hr. – sq. ft., the usage rate would be:

30 ft. x 128 ft. (3,840 sq. ft.) x 0.003 cu. ft./hr. per sq. ft. = 11.52 cu. ft./hr.

Infiltration loss depends on the tightness of the greenhouse or growth room and is calculated by multiplying the building volume (length x width x average height) x the air changes/hour x 0.000001 ppm x (the desired CO2 level – 410 ppm). Air change for a tight poly-covered greenhouse or an indoor growth room is about ½ volume air change/hr.

For a 30-foot by 128-foot x 12-foot high (46,080 cu. ft.) poly-covered greenhouse, the plant use = 46,080 cu. ft. x 0.5 changes/hr. x 0.000001 ppm x (1,000 ppm – 410 ppm) = 13.59 cu. ft./hr.

Total CO2 needed = 11.52 cu. ft./hr. + 13.59 cu. ft./hr. = 25.1 cu. ft./hr.

If you are using compressed CO2 with a yield of 8.5 cu. ft./lb., it would require 3 lbs./hr. (25.1 cu. ft./hr. ÷ 8.5 cu. ft./lb. = 3 lbs./hr.). With propane, the quantity would be about ¼ gallon/hr. (25.1 cf./hr. ÷ 108 cf./gal. = 0.23 gal.). With natural gas, the quantity would be about 0.24 ccf./hr. (25.8 cf./hr. ÷ 105 cf./ccf. = 0.24 ccf.).

CO2 Measurement

Several methods of measurement are available, including:

- Test kit ($20): air is pulled through test tube and level checked against a chart

- Hand held sampler (<$100): battery-operated blower pulls air across a sensor

- Monitor (>$500): uses dual beam absorption technology

- Computer control (>$800): uses infrared sensor technology

Injection Rate

Controlling the amount of CO2 added can be done by several methods:

- Constant rate based on the use plus infiltration: A time clock that stops flow at night and a relay shuts off ventilation if the ventilation system activates.

- Intermittent injection: This is based on the level as determined by a CO2 monitor/controller.

- Computer control: Integrates wind speed, light level, temperature and humidity.

There are many variables that affect yield increases due to CO2 enrichment including the crop, when its grown, the type and location of the greenhouse or growth room, distribution system for the CO2, etc.

The benefits of increased CO2 levels are significant for high-value crops, such as cannabis. The system must be designed properly to make it economic.