The total energy costs for average indoor cannabis grow operations account for 20 percent to 40 percent of total operating costs. By comparison, for a typical medium-size or larger brewery, energy use accounts for about 6 percent to 12 percent of total operating costs.

Because energy makes up a large portion of cannabis operating costs, efforts to reduce energy consumption can have a significant effect on a grow operation’s profit margin, as well as the business’s overall competitiveness. Many states with legalized cannabis markets also have their own energy-efficiency goals, making those state governments interested in working with the cannabis industry to reduce energy consumption. Also, many utilities have programs to help cannabis cultivators reduce their energy consumption.

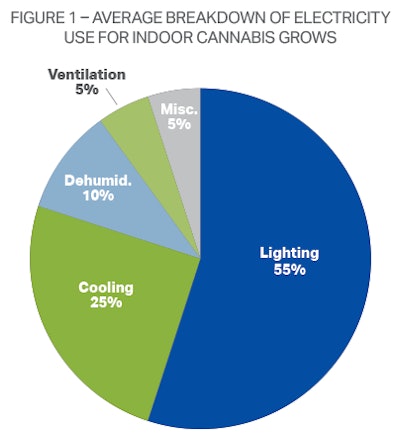

For indoor grows, lighting is typically the largest energy consumer, followed by cooling, dehumidification and ventilation, as shown in Figure 1 (p. 7). For the average indoor grow, the latter three grouped together account for about 40 percent of total energy consumption, making these mechanical systems an important area to examine. (Note that space heating, normally with natural gas, is not included in this breakdown, but is generally less than 10 percent of total energy consumption for indoor grows.)

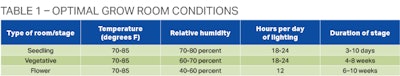

Optimizing energy consumption while maintaining the desired room conditions (shown in Table 1) for indoor grows can be challenging. The flowering stage, which requires the most intensive lighting and the longest periods of time (up to 10 weeks), is often the most challenging because of the tighter window at which you must maintain your humidity levels to limit mold, fungus and mildew growth. Flowering is made even more difficult by the fact that you must account for the dramatic changes in the sensible cooling load with lights-on versus lights-off periods. (The sensible cooling load is the amount of energy needed to lower the dry-bulb temperature, with no change in humidity.)

There are low-cost energy-efficiency measures, which can be applied to existing facilities, and alternative equipment options that mainly apply to expansions or new facilities. The following seven tips outline a few of these options:

TIP 1: Design and control for vapor pressure deficit (VPD) rather than relative humidity. Understanding the importance of VPD can help cannabis businesses save up-front capital costs as well as energy during daily operations. The VPD is the difference between the internal vapor pressure of a cannabis leaf relative to the vapor pressure of the air surrounding the leaf. The VPD determines the rate of transpiration, and VPD increases with higher room temperatures and with lower relative humidity. If the VPD is too low, condensation may occur on the leaves or buds, which can lead to fungus or mildew problems. If the VPD is too high, then the plants may become too dry or heat stressed.

Many growers try to limit the relative humidity of flower rooms to a maximum of 50 percent, without considering the temperature. By allowing a slightly higher room temperature of 75 to 80 degrees Fahrenheit (F) rather than 70 to 75 degrees F, and by considering the VPD—the room’s acceptable relative humidity levels can be higher. With these higher set points, the HVAC system (including cooling and dehumidification) can be sized at a smaller capacity, reducing the grower’s up-front equipment costs. In addition, the system’s energy consumption and energy costs during operations will be significantly lower.

TIP 2: Employee training regarding proper operating procedures, controls and good maintenance practices will help save energy.

TIP 3: If the grow is relying on rooftop units and electric reheat to control humidity, adding separate dehumidifier units to the flower rooms will reduce cooling and dehumidification costs significantly.

For grows with less than about 10,000 square feet of canopy, there are two main options for more efficient equipment:

TIP 4: Have separate and efficient dehumidification. When choosing new dehumidifier units for flower rooms, choose the most energy-efficient model available (for the capacity needed), which can reduce your dehumidification energy costs by up to 15 percent.

TIP 5: Use high-efficiency split ductless air conditioning/heat pump units. Although separate dehumidification units will still be required (as is the case with rooftop air conditioning units), there is some consensus among experts that using multiple “mini-split” units will be more efficient and cost-effective for the smaller grow operations than using rooftop units. There are high-efficiency split ductless heat pump/air conditioning systems available with seasonal energy efficiency ratings (SEER) of 25 or higher, compared to rooftop HVAC units with typical SEERs of 14 to 15. In addition, the split air conditioning units by design use much less fan energy compared to rooftop units.

*Chilled water systems or hot gas reheat (HGRH) systems may be cost-effective for grows smaller than 10,000 square feet, but these systems do tend to require a more sophisticated on-site energy/facility manager to properly operate and maintain, compared to a mini-split system with separate dehumidification units.

For grows with greater than about 10,000 square feet of canopy, there are at least two options, which both eliminate the need for separate dehumidifier units:

TIP 6: Consider chilled water systems. A well-designed chilled water system offers several energy-savings advantages, compared to the standard or split air conditioning systems with separate dehumidifiers described in previous tips. Standard rooftop air conditioning units are not designed to provide much latent heat removal, and the adjustments available to increase the system’s latent heat capabilities are limited. With a chilled water system, one can slow the fan speed and/or reduce the water temperature to achieve more latent heat removal. Thus, with a few modifications, a relatively simple chilled water system can achieve humidity control during lights-on periods without a separate dehumidifier. Portable dehumidifiers add heat to the space, which adds to the cooling load during lights-on periods.

TIP 7: Consider hot-gas reheat forced-air systems. These systems are more complex rooftop air conditioning systems, with added hot-gas reheat capabilities. This technology adds an additional condenser coil for reheat when needed. Compared to a standard dehumidifier (which has a cooling coil and a condenser coil that reheats the cooled and dehumidified air), this system adds an additional outdoor condensing coil in parallel with the reheat coil. This third coil and the associated controls allow the system to reject heat to the outdoors when cooling is required in the space (during lights-on periods), or to use the other condenser coil for reheat when there are minimal sensible cooling needs (during lights-off periods).